Enhancing our support of client projects: The impact of our first year as part of Sygnature Discovery

We can hardly believe it’s just over 1 year since we became part of Sygnature Discovery, and it seemed a good time to look back and reflect on what’s been achieved this year with the support of being part of a larger CRO operation. More importantly, we focus on the improvements to how we support our clients projects, that are a direct result of the change.

Our expanding team

Arriving as a group of around 32 people into our new facilities last March, it has certainly been a year of rapid growth as we welcomed 14 new members of staff across cell and protein science, structure determination, and our operations team. This number is soon to increase to around 50 staff as demand for our services increases, and as we are now working even more closely with the rest of the Sygnature organisation on a number of integrated drug discovery projects. The move to the Tytherington site with us all in one building has meant that even with this larger team communication between us is still efficient.

Investment in new equipment

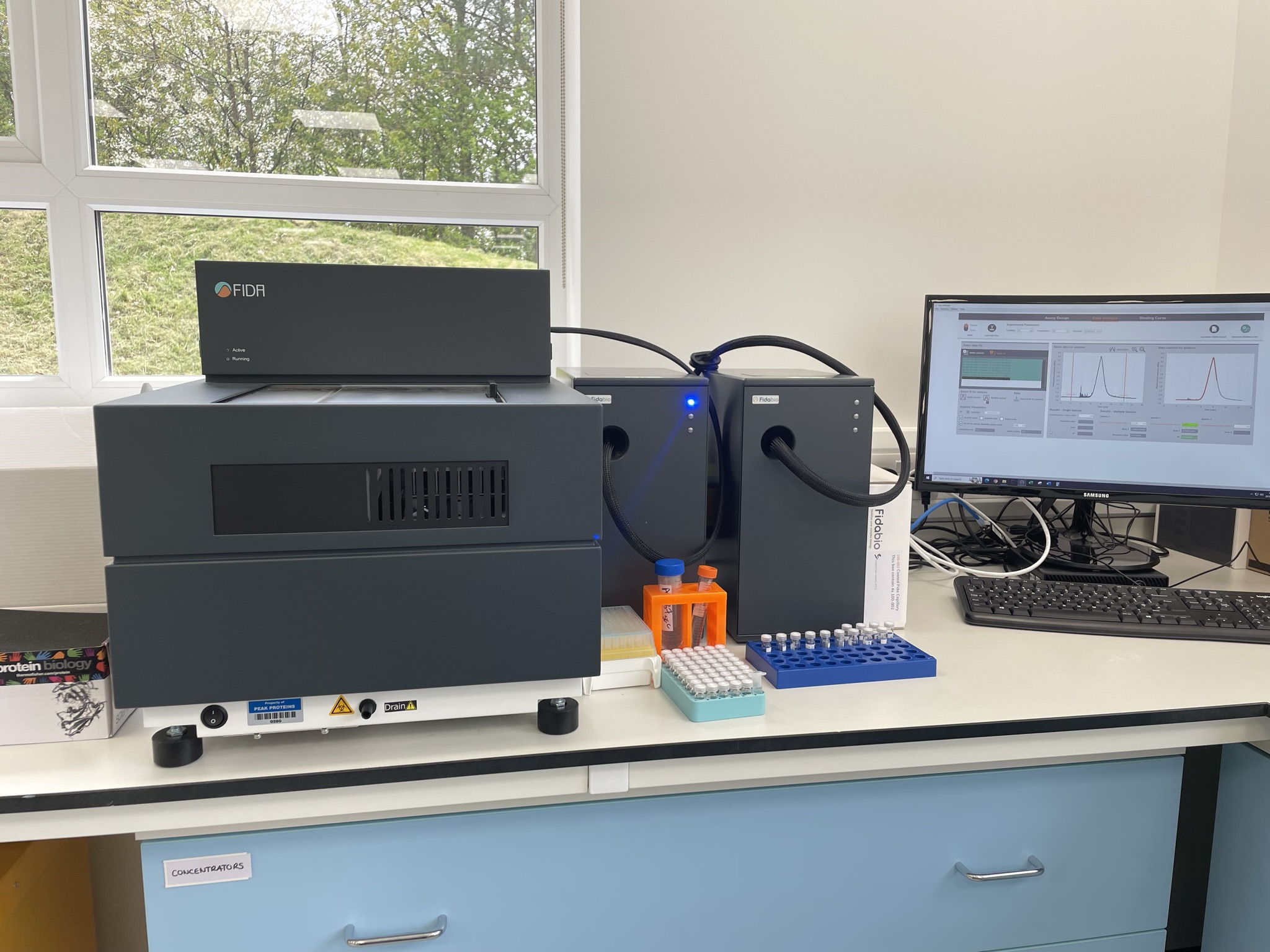

FIDA

With the arrival of more staff, we’ve needed to expand the available equipment and have been able to invest in some much needed AKTA systems for protein purification, and a cutting-edge platform such as FIDABio’s platform which has allowed us to take protein characterisation by Flow-Induced Dispersion Analysis (FIDA), to a whole new level (read our recent blog for more information).

Ultracentrifuge

In addition, to enhance our membrane protein purification capabilities, we also invested in a new Beckman Coulter ultracentrifuge which has greatly increased the volume of membrane protein preparations we can process at any one time and in turn, has increased our protein yields – a valuable step-forward when dealing with such tricky proteins.

Formulatrix Imager and JanSi Plate Hotels

As the number of crystallography projects within the company has been steadily increasing, new robotic equipment to speed our crystallisation throughput has come a high priority. The arrival of the Formulatrix Rock Imager 1000 and JanSi UVEXps plate hotels have made a huge difference to our ability to store and image higher numbers of crystallography plates at both 20oC and 4oC. Using the ROCK MAKER® software package, the protein ID, formulation, crystallisation plate type and composition are all recorded and programmed imaging schedules captured.

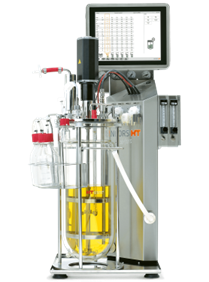

Bioreactor

Our cells team are not missing out either as we are shortly to receive our first bench-top bioreactor for E. coli expression which will allow us to perform up to a 10L culture volume in once monitored system which will remove any culture grows inconsistencies that inevitable occur when doing multiple shake flask cultures. This system also allows us to operate it as a single unit or as a parallel bioreactor with up to 6 vessels attached….so who knows where this could lead!

And finally, but most importantly, the integration into Sygnature led to increased collaborative working across the different science departments, primarily with bioscience and chemistry, some great interactions and discussions with experienced scientists and the opportunity to start collaborating on a number of internal and client programs such as the protein degrader project, spearheaded by Sygnature’s CHARMED approach to deliver rapid synthesis, screening and characterisation of potential bifunctional lead compounds for target protein degradation.

The future is certainly looking bright, and we look forward to seeing how we can work even better to deliver the protein science services our clients need to progress their drug discovery and research projects.

For more information on our protein services and what we can provide, please do have look at our website or get in touch with us at info@peakproteins.com and we’d be happy to discuss.