Peak Proteins Invests in New Equipment

As the number of crystallography projects within the company has been steadily increasing, new robotic equipment to speed the crystallisation pipeline had become high priority. Peak Proteins’ new premises, at Tytherington Business Village, was designed to incorporate such equipment. We had invested in two additional plate hotels at the end of 2021 and we were really excited when the first on one these was delivered to us at the end of April.

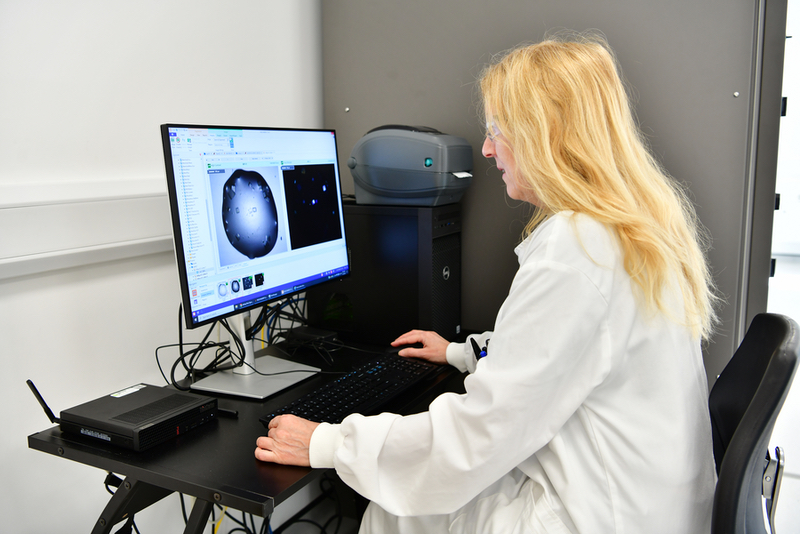

The Formulatrix Rock Imager 1000

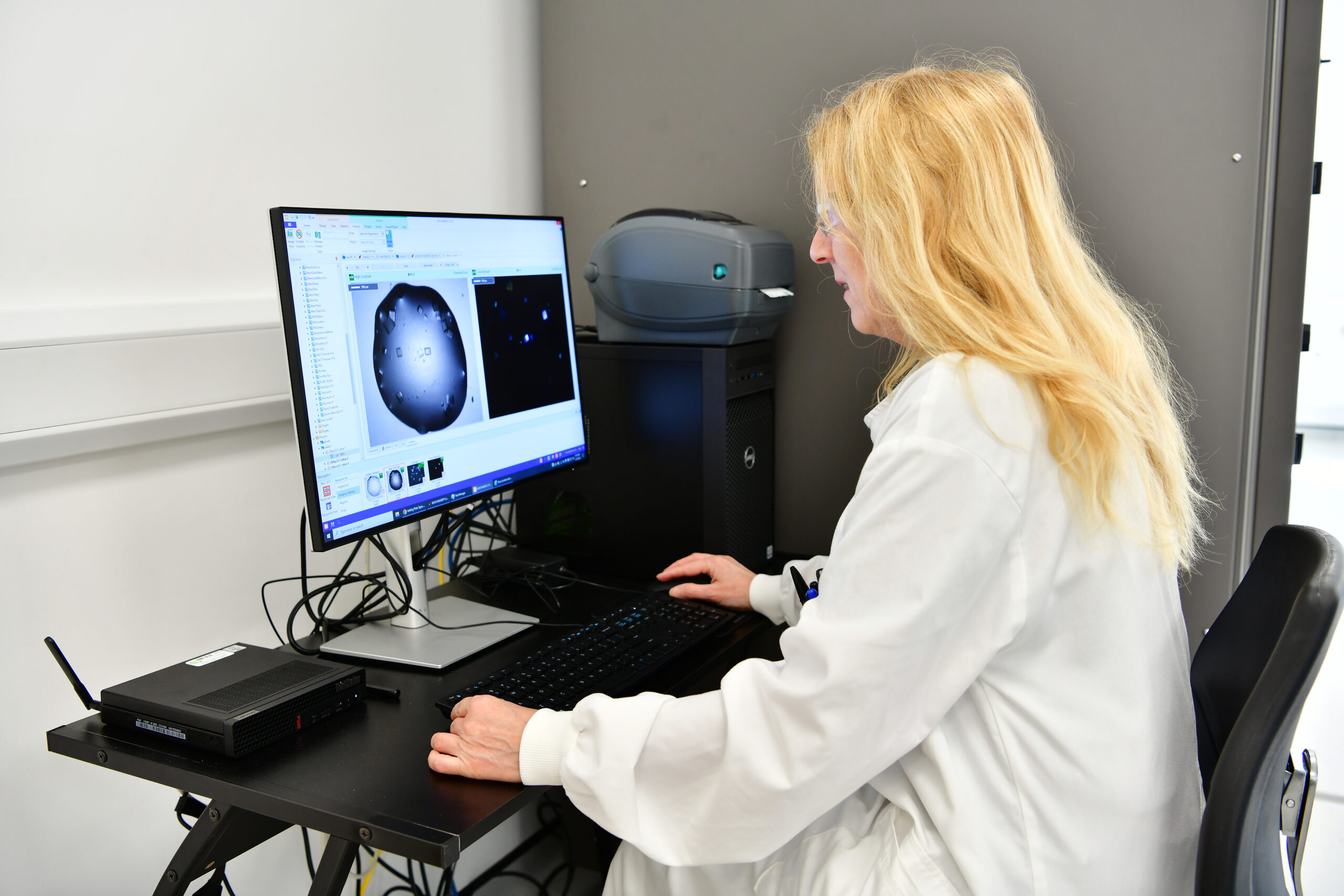

Our arrival was the Formulatrix Rock Imager 1000; a plate hotel capable of storing and imaging 970 SBS format crystallisation plates at a stable temperature and imaging them according to a user defined time schedule . Using ROCK MAKER® software package, the protein ID, formulation, crystallisation plate type and crystallisation screen composition are all recorded. Programmed imaging schedules capture images using UV and visible light (with the optional use of cross polarisers), allowing the appearance of crystals within the protein drops to be monitored closely over time. Viewing and scoring these images via a Web based interface further streamlines the whole structural determination process.

Dr Tina Howard, Director of Structural Biology commented, “Adding the Rock Imager system to our existing equipment has significantly enhanced our capacity to handle crystallisation plates and projects. Boosting the number of plates imaged overnight has given us back so much more time during the day. Being able to access and assess the images at on our individual computers has also provided much needed flexibility.”

Rock Imager is currently operating at 20°C. Our capacity for screening at 4°C will also be substantially increased with the imminent arrival of a JANSi UVEXps plate hotel. Again, this will enable us to record full experimental details alongside the automatically acquired drop images, this time with lower temperature storage options possible. Similarly, the team can all view, score and annotate their experiments from their own desks while planning their next round of optimisations and which crystals to harvest next.

“As well as the allowing us to carryout crystallisations screening far more as efficiently, adding both of these fully automated plate hotels, will also allow us to explore crystallisation at alternative temperatures in our existing incubators” added Tina. “There nothing like the excitement of seeing a new crystal appear and progressing it via x-ray data collection to a model of how the molecules are arranged within that crystal.”

Crystallisation is just the one of many vital steps in the middle of this whole process, from choosing the right construct, expressing and purifying it and the subsequent analysis of the x-ray data. Our staff at Peak Proteins have considerable experience expressing and purifying a wide range of classes of protein and structural determination by x-ray crystalography. Should that be of interest to you and your research, please don’t hesitate to get in touch with us via our website or by email (info@peakproteins.com). We look forward to hearing from you.

Formulatrix Rock Imager 1000

Using the ROCK MAKER® software package